Hydroxypropyl methyl cellulose (HPMC) is a non-ionic cellulose prepared from natural polymer materials through a series of chemical processes. It contains almost all the properties of methyl cellulose (MC) and is your first choice for producing quality building material additives. To meet the needs of environmental protection, our product has high water retention, dispersibility, good fineness, good processability and easy handling. Dissolving properties. It is suitable for dry mortar construction, internal and external wall putty powder emulsion (paste), adhesive, caulking agent, interface agent, coating, self-leveling agent for new building materials.

Product characteristics

1. Operability: It can enhance the plasticity of mortar in construction projects and improve the efficiency of painting.

2. Water retention: water retention is enhanced to help solve the problems of cement or gypsum building materials drying too fast, poor hardening or insufficient hydration and cracking.

3. Adhesion: improve the plasticity of mortar, so that the mortar can better adhere to the substrate.

4. Anti-slip: In the construction project, due to its thickening effect, it can prevent the problem of slippage between mortar and substrate.

What are the main technical indexes of hydroxypropyl methyl cellulose (HPMC)?

The five indexes are hydroxypropyl content, methoxy content, viscosity, moisture and ash content. The ratio of hydroxypropyl content to methoxy content should be appropriate, the water retention will be good, not just which index is high. Viscosity: When the viscosity is less than 100,000, the water retention increases with the increase of viscosity. However, if the viscosity is more than 100,000, it has little effect on water retention. Another important indicator is the ash content. The popular one can be understood as the impurity of the product. The lower the ash content, the higher the purity, the better the product. The ash content of general products is around 5%, and for better domestic quality, the ash content is around 2-3 percentage points.

What is the choice of HPMC viscosity when producing putty powder dry mortar?

Methyl cellulose MC and hydroxypropyl methyl cellulose (HPMC) have stable chemical properties. Mildew resistance and water retention are not affected by changes in pH.

Viscosity can be used between 50,000 and 200,000, but in production, higher viscosity is better. Viscosity is inversely proportional to bond strength. The higher the viscosity, the lower the strength.

Regarding the quality of cellulose, mainly the viscosity, it can be tested using a rotational viscometer; or it can be compared by a simple method.

For the comparison, take 1 gram of cellulose of the same viscosity. Add 100 grams of water, put it in a disposable cup and pour it out at the same time. Observe which one dissolves faster, has better clarity and thickens better. The better the transparency, the less impurities.

It is used for low-grade putty powder for interior walls, which has certain thickening and water retention effect and can increase leveling. However, it cannot be used for waterproof putty and external insulation dry mix.

This is because these cellulose will react with cement, grey calcium powder and gypsum powder, inorganic binders.

Many people think that these cellulose are alkaline, and generally cement and grey calcium powder are also alkaline. It is thought that they can be used in combination. However, CMC and CMS are not single elements.

The chloroacetic acid they use in the production process is acidic. The residue of the cellulose production process reacts with cement and gray calcium powder. So they cannot be combined. Many manufacturers have suffered great losses, which should be taken seriously.

How to judge the quality of hydroxypropyl methyl cellulose (HPMC) in a simple and intuitive way?

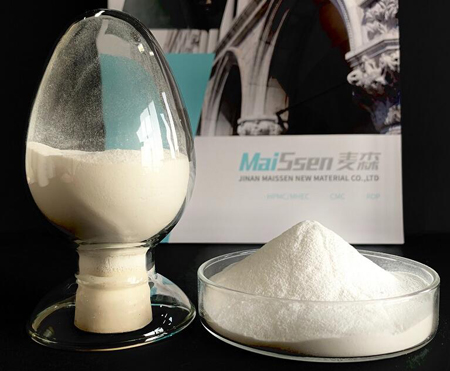

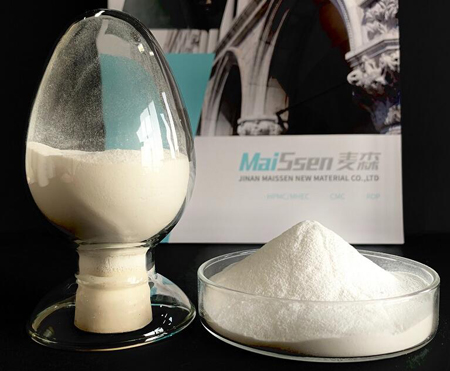

Whiteness: Although the whiteness does not determine whether HPMC is good or not, if brightening agent is added in the production process, it will affect its quality. However, most of the good products are white.

Fineness: The fineness of HPMC is 80 mesh and 100 mesh. Generally speaking, the finer the fineness, the faster it dissolves.

Transmittance: Put hydroxypropyl methyl cellulose (HPMC) into water to form a transparent colloid and see its transparency. The better the transmittance, the less insoluble matter. Vertical reactor has good permeability, horizontal reactor is worse, but it does not mean that the quality of vertical reactor is better than kettle type. The quality of the product is determined by many factors.

Specific gravity: The specific gravity is moderate. If the ratio is too large or too small, it may be the result of uncontrolled production process.

What are the dissolution methods of hydroxypropyl methyl cellulose (HPMC)?

Hot water dissolution method: Since HPMC is insoluble in hot water, the initial HPMC can be dispersed uniformly in hot water and then dissolved rapidly during the cooling process. Two typical methods are described as follows.

Put the required amount of hot water into a container and heat it to about 70°C. Gradually add hydroxypropyl methylcellulose under slow stirring, HPMC floats on the water surface and gradually forms a slurry, stirring to cool the slurry.

Add 1/3 or 2/3 of the required amount of water to the container, heat to 70°C, disperse HPMC according to 1) to prepare hot water slurry; then add the remaining amount of cold water to the hot water slurry, stir and cool.

Powder mixing method: HPMC powder is mixed with a large amount of other powdery substances, mixed thoroughly with a mixer, and then dissolved with water. At this time HPMC can be dissolved without lumping, because there is only a little HPMC in each tiny corner. the powder will dissolve immediately after contact with water. This method is used by putty powder and mortar manufacturers.

Does putty powder have anything to do with HPMC?

The powder quality of putty powder is mainly related to the quality of calcium ash, but not to HPMC. Low calcium content of calcium ash and improper ratio of CaO to Ca(OH)2 in calcium ash can cause powder drop. If it is related to HPMC, then the water retention of HPMC is very poor, which will also cause pulverization.

Interior and exterior wall putty powder formula

Heavy calcium 700-800KG Gray calcium 300-200KG HPMC 4-5KG (starch ether, pure green, grass native, citric acid, polyacrylamide, etc. can be added as appropriate) Exterior putty powder: cement 350KG heavy calcium 500KG quartz sand 150KG latex powder 8-12KG cellulose ether 4-6KG starch ether 0.5KG wood fiber 2KG. (The formula is for reference only, the specific construction is adjusted according to the region and actual situation).

What is the relationship between the viscosity and temperature of HPMC? What should I pay attention to in the actual application?

The viscosity of HPMC is inversely proportional to temperature, i.e. viscosity increases as temperature decreases. We usually refer to the product viscosity as the result of testing 2% aqueous solution at 20 degree Celsius. In practical application, attention should be paid to areas with large temperature difference between winter and summer. It is recommended to use a lower viscosity in winter, which is more conducive to construction. Otherwise, when the temperature is low, the viscosity of cellulose will increase, and when scraping, the feel will be heavy.

If you have any questions about HPMC, please feel free to contact us.