HPMC Water Retention

HPMC(hydroxypropyl methyl cellulose) is one of the most important additives in dry mix mortar. HPMC is very important in the dry mortar formulation. In construction, HPMC is often used as a thickener or binder in cement, mortar, or plaster formulations.

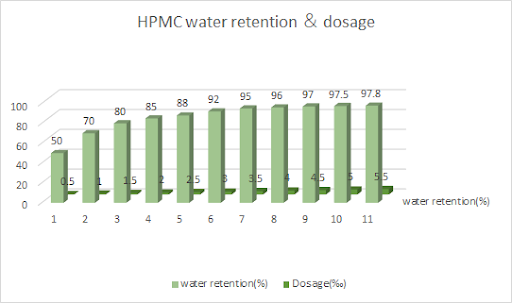

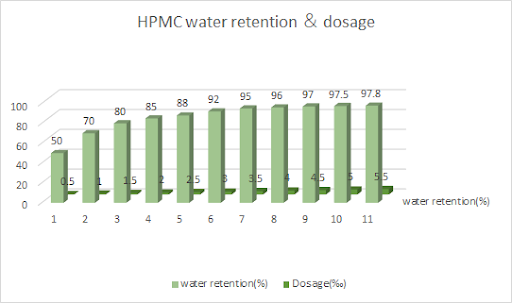

HPMC solution has its own molecular structure characteristics, so that the water in the mortar is not easy to lose, and is gradually released over a long period of time, giving the mortar good water retention and workability. Water retention is the most important index and the basic standard of HPMC. Water retention rate refers to the amount of water retained by the freshly mixed mortar on the absorption substrate.

HPMC water retention capacity is influenced by various factors such as the degree of substitution, particle size, and the concentration of the HPMC in the mixture. HPMC can help to improve the quality and performance of construction materials by providing enhanced water retention, better adhesion, and improved workability.

HPMC Water Retention Test Methods

Normally, we have two ways to do the HPMC water retention test, vacuum method and Filter paper method.

● Vacuum Method for HPMC Water Retention Test

-Moisture in the mortar after suction filtration

-Moisture in the mortar before suction filtration

Refer to JC/T517-2005 & JISA 6904-1976.

Fill the Buchner funnel with the stirred mortar, place it on the suction filter bottle, start the vacuum pump, and filter under the negative pressure of 400±5mm pump column for 20 minutes, and then calculate according to the following formula according to the water volume in the mortar before and after the suction filter Water retention rate:

Water retention(%) = Moisture in the mortar after suction filtration/Moisture in the mortar before suction filtration ×100

This HPMC water retention test method needs to be done by professional equipment, therefore the test result is more accurate, but the cost is high.

● Filter Paper Method for HPMC Water Retention Test

1) Test equipment: Mortar mixer, Electronic balance

2) Material: filter paper, standard sand, cement, sypsum

3) Test Mothed:

The filter paper method judges the water retention of HPMC by the water absorption of the filter paper.

Composed of a certain height of metal ring experiment mold, filter paper and glass pallet.Below the experimental mold are 6 layers of filter paper, the first layer is fast filter paper, and the remaining 5 layers are slow filter paper. Use a balance to weigh the glass pallet and 5 layers of slow filter paper, pour the mortar into the experimental mold and scrape it flat, place the experimental mold upside down on the filter paper for 15 minutes, and finally weigh the pallet and 5 layers. Calculated according to the following formula:

M=(M1-M2)/S

M: water loss g/mm²

M1: The weight of pallet and 5 layers filter paper

M2: The weight of pallet and 5 layers filter paper after 15 minutes

S: Experimental mold area mm²

By this method, you can see the water absorption of filter paper directly. The lower filter paper water absorption, the water retention is better.

Jinan Maissen New Material Co., Ltd is the professional HPMC manufacturer for dry mix mortar industry. We offers reliable and stable supply of HPMC with various specifications of water retention to meet different requirement on HPMC. If you have any inquiry, please feel free to contact us for more details.