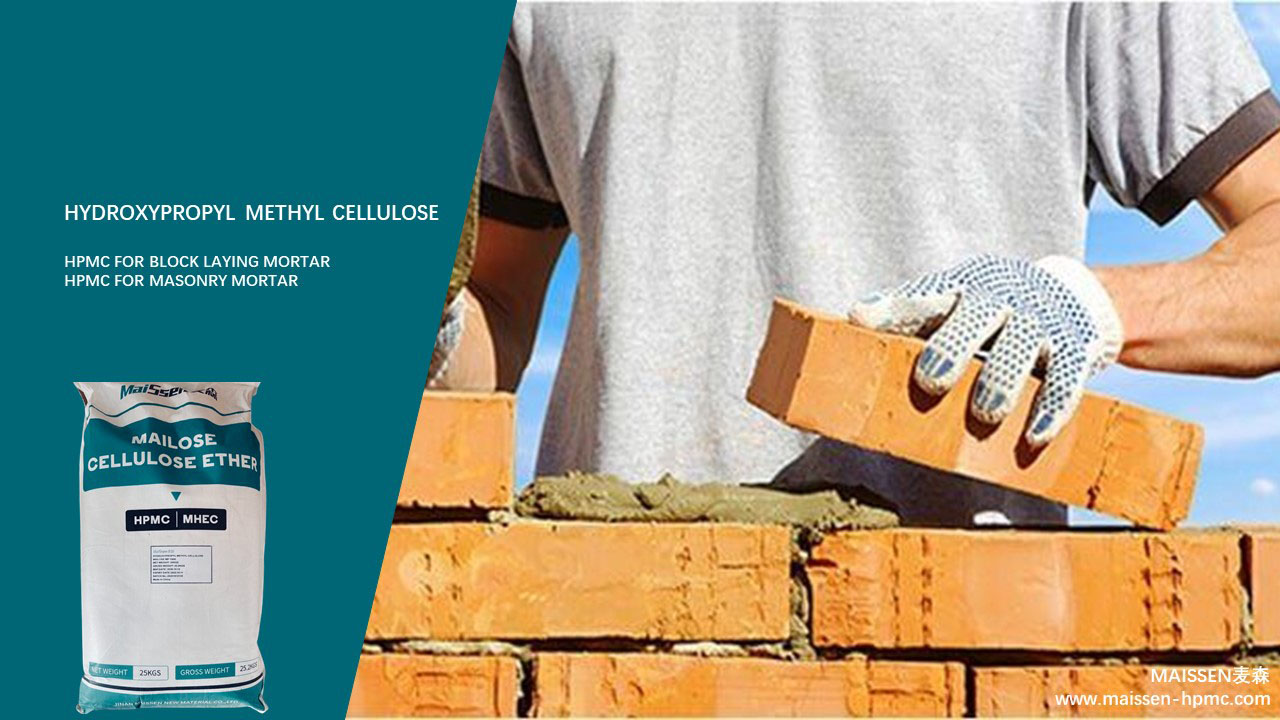

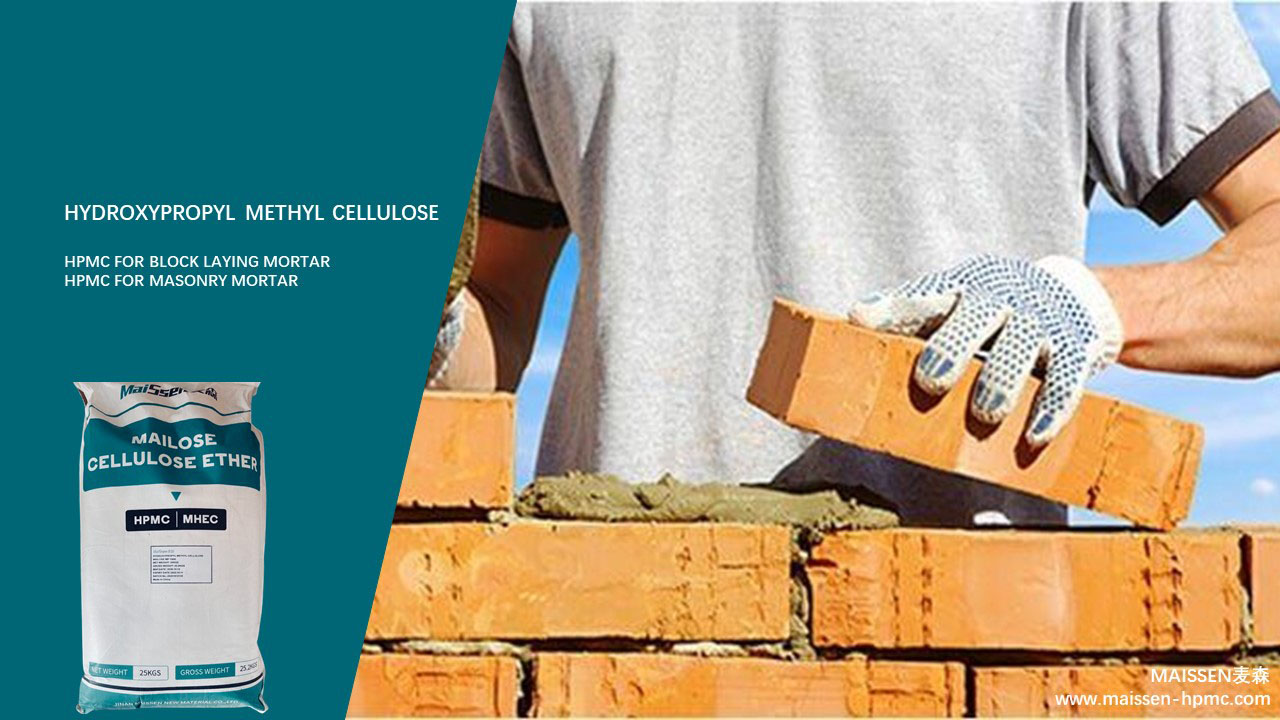

In recent years, with the continuous development of exterior wall insulation technology, the continuous progress of cellulose production technology, and the excellent characteristics of HPMC itself, hydroxypropyl methylcellulose HPMC has been widely used in the construction industry.

In order to study the mechanism of the interaction between HPMC and cementitious materials, this paper investigates the improvement effect of HPMC on the bonding performance of cementitious materials.

Setting time

The setting time of concrete is mainly related to the setting time of cement, and aggregate has little effect, so HPMC can be used instead of the setting time of mortar on non-dispersed underwater concrete, and the setting time of mortar is affected by the water-cement ratio and cement-sand ratio, so in order to evaluate the effect of HPMC on the setting time of mortar, mortar fixed water-cement ratio and cement-sand ratio.

The experimental responses showed that the addition of HPMC had a significant retarding effect on the mortar mix. With the increase of HPMC content, the setting time of mortar was prolonged. With the same amount of HPMC, the underwater molding mortar took longer time than molding in air. When measured in water, the setting time of HPMC mixed mortar was 6~18 h. Compared with the blank test, the final setting was delayed 6~22 h. Therefore, HPMC should be used in combination with early strength agent.

HPMC is a kind of high polymer. It is a macromolecular linear structure with hydroxyl group on the functional group. It can form hydrogen bonds with mixed water molecules to increase the viscosity of mixed water. long molecular chains of HPMC will attract each other and combine HPMC molecules to form a network structure to wrap the cement and mixing water. As HPMC forms a network structure similar to the effect of film and cement wrapping, it can effectively prevent the evaporation of water in mortar and delay or slow down the hydration rate of cement.

Bleeding

Mortar is similar to concrete in terms of water secretion, which will cause serious aggregate settlement, resulting in an increase in the water-cement ratio of the top mud, large early plastic shrinkage cracking of the mud, and relatively weak surface strength of the mud.

When the content is above 0.5%, there is basically no longer bleeding phenomenon. This is because when HPMC is mixed into the mortar, HPMC has a membrane mesh structure, and the hydroxyl group is adsorbed on the long chain of polymer. It makes the cement and mixing water flocculate in the mortar to ensure the stability of mortar structure. After adding HPMC into mortar, many independent tiny bubbles will be formed. These bubbles are evenly distributed in the mortar and hinder the deposition of aggregates. This technology has a great impact on the performance of HPMC cementitious materials, such as dry mortar, which is commonly used to prepare polymer mortar cementitious composites with good water retention and water resistance.

Mortar water requirement

When the amount of HPMC is very small, it has a great influence on the water demand of mortar. When the swelling degree of fresh mortar is basically the same, the amount of HPMC and mortar water demand in a certain period of time is a linear change, mortar water demand first decreased and then increased significantly. Many tiny independent bubbles, these bubbles play the role of lubrication. The mortar fluidity is improved. The water requirement of mortar increases with the increase of volume when the mixing amount is more than 0.025%. This is due to the further improvement of the reticular structure of HPMC, the shortening of the flocculation space on the long molecular chain, the attraction and cohesion of mortar, and the decrease of mortar fluidity. Therefore, the slurry shows an increase in water demand at the same degree of expansion.