Hydroxypropyl methyl cellulose ether is a synthetic polymer made from natural cellulose by chemical modification. Cellulose ether is a derivative of natural cellulose. The production of cellulose ether is different from synthetic polymers. its basic material is cellulose, a natural high molecular compound. Due to the special structure of natural cellulose, the cellulose itself does not have the ability to react with etherifying agents. However, after the treatment of swelling agent, the strong hydrogen bonds between and within the molecular chains are destroyed, the active release of the hydroxyl group becomes alkali cellulose with stress ability, and the cellulose ether is obtained by converting the —OH group into —OR group through the reaction of etherifying agent.

Mailose MP 200K(S)

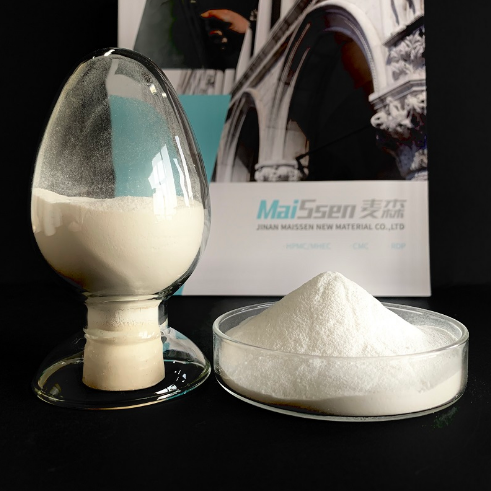

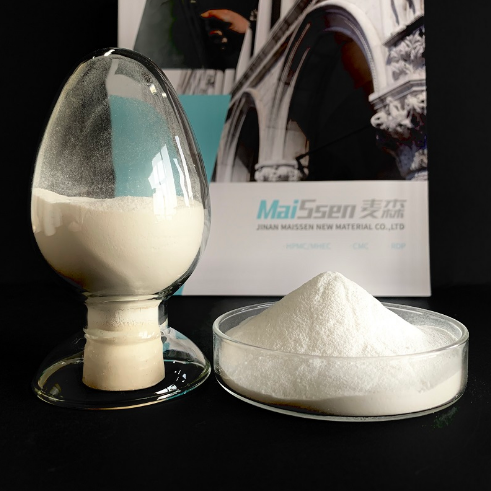

Hydroxypropyl methyl cellulose is a white or slightly yellowish powder, and odorless, tasteless, non-toxic. It can dissolve in the solvent mixed with cold water and organic matter to form a transparent viscous solution. Aqueous solution has surface activity, high transparency, strong stability, dissolution in water is not affected by pH. surface treated hydroxypropyl methyl cellulose HPMC has thickening and antifreeze effects in detergents, detergents, laundry detergents, shampoos, and shower gels, and has water retention and good film-forming properties for hair and skin. With the substantial increase in basic raw materials, cellulose (anti-freeze thickener) used in washing and daily chemical applications can greatly reduce costs and achieve ideal results.

Industrial grade HPMC has construction grade, surface treated grade and etc. surface treated hydroxypropyl methyl cellulose HPMC is often used in shampoo, dishwashing liquid, laundry detergent and other aspects to adjust the viscosity. Construction grade hydroxypropyl methyl cellulose is generally used in mortar, putty, diatom mud, etc. The viscosity is generally required to be above 100,000 viscosity, which belongs to high viscosity. Surface treated hydroxypropyl methyl cellulose generally requires a viscosity of 200,000 and it is basically equivalent to the viscosity of mortar.

If you want to know more information about Hydroxypropyl methyl cellulose, please contact us. We will provide professional answers.